The Collapsed I-35W, Minneapolis, Minnessota, USA

___________________________

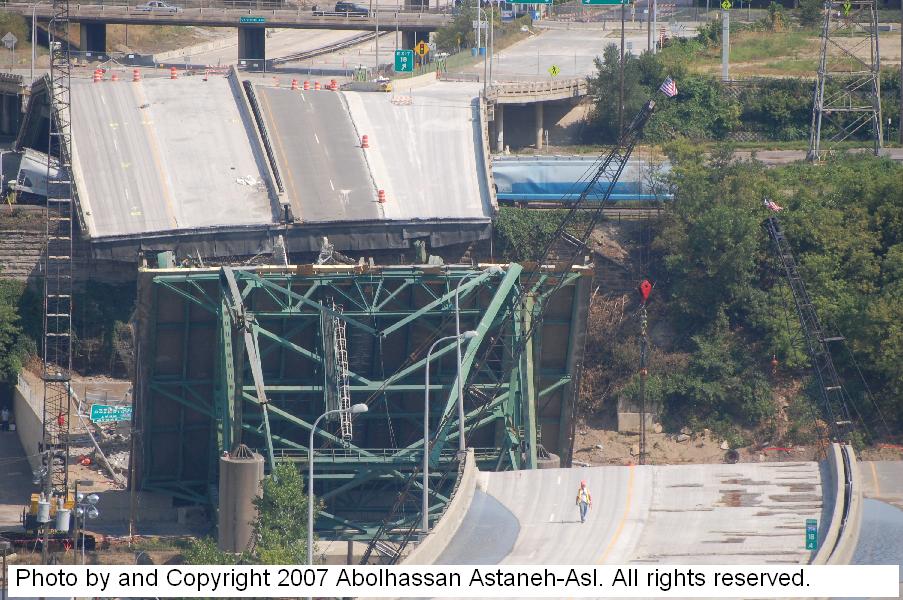

On August 1st, 2007, the steel truss bridge carrying I-35W interstate highway, collapsed suddenly resulting in tragic death of 13 people and injury to more than 100 others. In the aftermath of the collapse, Professor Abolhassan Astaneh-Asl of the University of California, who specializes in behavior, design, and investigation of failure of structures , specially steel and composite buildings and bridges, initiated a study of the collapse which continues to present time. He traveled to Minneapolis 9 days after the collapse and stayed there for 11 days collecting data , particularly perishable data on the collapse with main goal of learning lessons from this tragic event and understanding what caused such a brittle and sudden collapse of entire span and to devlop technologies that can be used to retrofit similar bridges , as well as to design new bridges , that will not collpase in such a tragic and catastrophic manner causing death and injury to people and chaosin the local as well as regional transportation networks.

______________________________________

Some of the questions to be answered by this investigation:

1. What lessons we can learn from this tagedy to prevent it from occurring in the future?

2. Could the tragic collapse be predicted prior to the collapse and the tragedy be prevented?

3. What was the role of lack of redundancy in the steel trusses in initiation and progressive collapse?

4. Were the gusset plates "U10" the main culprit in the collapse?

5. Do other cases of gusset plate failure, such as those in the DeSoto, Blatnik and other bridges, relates to this tragic collapse of I-35W

6. Was the construction activities and equipment on the bridge at the time of collaspe a contributor to the tragic collapse of the I-35W?

7. Could lessons learned from the gusset plate failure of the I-90E Bridge in 1996 be used and applied to this bridge?

8. Is the replacement bridge a good option specially from safety and functionality points of view?

Some of the activities to be done as part of this project:

1. Provide an objective and critical review of the NTSB's ongoing investigation into the tragic collapse of the I-35W

2. Provide an objective and critical review of the 'Fracture critical" studies done by the URS corporation prior to collapse of the I-35W done for MN DoT (to be posted soon).

3. Provide an objective and critical review of the effects of ongoing construction activities by PCI at the time of collapse and the material and equipment placed on the bridge on the collapse

4. Provide an objective and critical review of MN DoT's maintanence and inspection regemes prior to collapse

5. Provide an objective and critical review of the fatigue studies of the I-35W done prior to collapse by the University of Minnesota researchers fro MN DoT..

6. Prvide an objective and critical review of the FHWA policies regarding retrofit of "structurally dificient" bridges.

7. Prvide an objective and critical review of the " National Bridge Inventory Rating System" specially with regard to gusset plates, splice plates and in general steel trusses.

|

PROGRESSIVE COLLAPSE OF STEEL TRUSS BRIDGES,

THE CASE OF I-35W COLLAPSE (PDF file, 0.4MB)

By Abolhassan Astaneh-Asl, Invited Keynote Speech Paper, Proceedings, 7th International Bridge Conference, Portugal, June, 2008.

Abstract: Steel deck truss bridges, being determinate systems and not having redundancy,

can progressively collapse over the entire span, if a single primary member or gusset plate

connection of the main trusses fails. One of the recent tragic examples of such progressive

collapse of the entire bridge due to loss of a single gusset plate is the case of I-35W steel deck

truss bridge located in the city of Minneapolis in United States which collapsed entirely on

August 1, 2007 resulting in deaths of 13 people and injury to more than 100 others. This paper

presents a summary of the structure of the bridge, the condition of the bridge prior to collapse,

a likely scenario for its progressive collapse and provides lessons learned and design

recommendation in the conclusion section. The recommendations can be used in design of

new and in the retrofit of existing steel truss bridges to mitigate this serious life safety hazard. (Full Paper, *.pdf)

________________________________ |

WASHINGTON — Federal accident investigators next week will issue their final report on last year's fatal highway bridge collapse in Minneapolis. The findings are likely to spur calls for greater spending on bridges across the nation, according to civil engineering groups........

Several issues argue for additional spending on bridge safety, according to leading engineers, including University of California-Berkeley, engineering professor Abolhassan Astaneh. Astaneh is working for a law firm that represents victims in the collapse.

Among some of the potential issues:

• Key structural elements known as gusset plates were buckled at least two years before the accident, according to photos released in the investigation.

The NTSB announced in January that the plates, which hold girders together, were half as thick as they should have been and likely triggered the collapse.

• The I-35W bridge was an older design that would topple, much like a house of cards, if any single girder or joint failed.

(Click here for full news story)

____________________________________

Officials disagree on value of 35W bridge report,

by Sea Stachura, Minnesota Public Radio, June 4, 2008

Rochester, Minn. — The report was written by UC Berkeley structural engineering professor Hassan Astaneh, an internationally recognized authority on steel bridges. Astaneh concluded that 300 tons of material on the bridge at the time of the collapse, and an additional two inches of pavement added to the bridge years before, led to the bridge disaster. He also concluded that MnDOT and its consulting firm, URS, should have examined the 35W bridge's gusset plates under Federal Highway Administration standards. The report was the keynote address at the International Conference on Steel Bridges in Portugal. . ... (Click here for full news story)

__________________________________

World-class engineering expert Hassan Astaneh has spent a significant amount of time studying the 35W bridge collapse and the apparent failure of gusset plates. In a paper delivered Tuesday, Astaneh concluded MnDOT and the consulting firm it hired could have prevented the collapse if they had noticed several crucial bits of information. In his report, Astaneh outlines several contributors to the collapse. Several layers of concrete were added to the roadway surface in 1998. The 35W bridge deck was nine inches thick, and normally a bridge’s deck is six to seven inches thick. And while a bridge is designed to bear up to two times its intended weight for the purpose of a safety net, the extra weight cut into the bridge’s safety net tremendously....... (Click here for full news story)

___________________________________

Rochester, Minn. — Hassan Astaneh's analysis of the 35W bridge collapse concludes that MnDOT, the construction company PCI and URS Corporation, the consulting firm that evaluated the bridge, could have prevented the collapse.Astaneh is a professor in University of California Berkeley's Civil and Environmental Engineering Department whose work includes studies on the collapse of the World Trade Center for the National Science Foundation. He's been hired as a consultant by one of the lawyers representing some of the victims of the bridge collapse. His paper on the 35W bridge disaster is the keynote address at International Conference on Steel Bridges. Astaneh provided MPR News with an advance copy. ... (Click here for full news story)

__________________________

When the steel truss of the I-35W bridge in Minneapolis broke into three pieces and tumbled into the Mississippi River on August 1, Berkeley professor of civil and environmental engineering Abolhassan Astaneh-Asl began investigating. He booked a hotel room overlooking the wreckage and boarded a plane headed east. For nine days he took photos, interviewed survivors, consulted other engineers and studied the bridge’s designs and reports to reconstruct the event and prevent similar catastrophes in the future, whether benign or intentional.

“I’m trying to figure out how this bridge lasted so long,” Astaneh-Asl told the audience at the Society of American Military Engineers’ Brown Bag Technical Seminar in San Francisco in late August. “The bridge was fracture critical. By fracturing one member, the entire system collapsed like a house of cards.... (Click here for full news story)

___________________________________

St. Cloud, Minn. — National Transportation Safety Board engineers spent the day suspended under the Desoto bridge in St. Cloud, in a bucket, attached to a crane on a truck.....

........

"What we saw with the St. Cloud bridge was a very slight, almost imperceptible, bend in gusset plates in four locations which indicated there was some type of load factor causing them to have that slight bend in a symmetrical fashion," McFarlin said.

But another bridge expert thinks that description doesn't go far enough, and referring to it as a "bend" doesn't show

how serious the problem is.

Hassan Astaneh, professor of structural engineering at the University of California-Berkley, is an expert on steel truss bridges.

Astaneh is doing his own investigation of the St. Cloud bridge. This week he's spent hours under the span, taking pictures and describing his findings into a tape recorder.

Astaneh said what's happening to the St. Cloud bridge is gusset plate buckling, something more serious than bending.

"All the evidence I see here is buckling. If it proves to be buckling, it means over stressing of this truss bridge," Astaneh said.

That Astaneh said could come from the extra concrete that was layered on the bridge over the years, something MnDOT officials have also suggested.

Astaneh, who also investigated the I35-W bridge collapse in Minneapolis, hopes his work in St. Cloud adds to knowledge about why certain bridges collapse when one piece of their structure fails.

"All I'm trying to find out is what we can learn. Whether or not this buckling could end up progressively collapsing this bridge," Astaneh said.

Astaneh's goal is to help engineers and lawmakers understand how to best shore up the nation's aging bridges and also protect them from terrorist attacks. ....(Click here for full news story)

__________________________________

ST. CLOUD – Internationally-known steel engineer Hassan Astaneh examined the Desoto bridge in St. Cloud Thursday to gain insight on bridge strength and steel structures.

Dr. Astaneh is a UC Berkeley Engineering Professor. He applauds MnDOT for closing the bridge once the bending gusset plates were found.

"Anytime you see buckling of gusset plates or members… the first thing you have to do as an engineer in charge of that bridge is to close it."

Dr. Astaneh was at the site of the World Trade Center in 2001. It was his verdict of bending steel weakened by heat that brought down the Twin Towers.

Now, he is researching the Desoto bridge and 35W collapse. He intends to focus particularly on the apparent failure of gusset plates. In fact, Dr. Astaneh’s doctoral dissertation was on gussets and how they fail.(Click here for full news story)

_________________________________

Bridge investigation: Six months of digging but few answers

by Sea Stachura, Minnesota Public Radio, February 1, 2008

Washington, D.C. — Former NTSB Chairman Jim Hall says a public hearing should be called on the collapse to clear up some of the public confusion, and rumors of politics in the board's investigation.

Rosenker's statements have raised questions about the investigation for structural engineer Hassan Astaneh. Astaneh is a professor at University of California, Berkeley and an expert in gusset plates.

"I'm beginning to really feel like we should get more information. They should provide more information to the public before they make such a strong statement [about the cause of the bridge collapse]," Astaneh says.

Astaneh says he is also surprised at Rosenker's assertion that bridge inspections by MnDOT and its contractors wouldn't have found the underdesigned plates.

That is the case during routine inspections, but Astaneh says a bridge should undergo more rigorous scrutiny before it is subject to major construction or expansion. The 35W bridge was undergoing some major repair work at the time of the collapse.

"Inspection of a bridge, especially if you are doing construction on it -- is not just going to be field inspection and checking the fatigue and corrosion. Inspection means you look at the whole system and analyze it," Astaneh says. "That's why MnDOT paid URS to do such analysis before undertaking the current construction." ....(Click here for full news story)

_________________________________

Steel plates connecting steel beams in the Interstate 35-W bridge in Minneapolis were too thin by half and fractured, "the critical factor" in the collapse that killed 13 people and injured 145, the National Transportation Safety Board said Tuesday.........

.............................................

Abolhassan Astaneh-Asl, a professor of civil and environmental engineering at the University of California at Berkeley and an expert on gussets, spent 10 days in Minneapolis after the collapse gathering information for his own research.

"I concluded that the construction load may have been the last straw," he said..........(Click here for full news story)

_________________________________

Three investigations search for cause of I-35W bridge collapse,

by Sea Stachura, Minnesota Public Radio, October 15, 2007

Minneapolis, Minn. — An NTSB investigation begins with the on-scene data collectors. It ends with the NTSB board. The five board members pronounce the final verdict on what caused the disaster. Former NTSB board member John Goglia describes the whole process as kiss and tell............

There are also other, less formal investigations underway. University of California-Berkeley structural engineering professor Hassan Astaneh is studying the bridge for his research on protecting bridges against terrorist attacks.

Astaneh says there seems to be broad agreement that the basic cause of the collapse was a fracture in the bridge structure.

"I think the argument is where did the fracture occur? Because without a fracture you can't collapse anything. There has to be a fracture," he says.

Astaneh's theory is the collapse is linked to repairs to the bridge underway at the time of the collapse. He believes a heavy load on one end of the bridge put the structure off balance. Traffic flowed asymmetrically on the bridge, further unsteadying it, then workers removed part of the bridge deck. He says that may have put too much weight on weak steel beams. .......(Click here for full news story)

__________________________________

Post-Minneapolis, Engineers Go Gonzo to Bombproof U.S. Bridges

Popular Mechanics | Alex Hutchinson | September 26, 2007

How does disaster strike for the Department of Homeland Security these days? A terrorist drives a car packed with explosives onto a major cable-supported bridge, parks it next to a crucial binding and detonates it. Splat! Paint, of all things, is everywhere -- but the cable remains intact, and the span stays standing. ..........

...... The collapse of the I-35W bridge in Minneapolis may have been the result of maintenance problems rather than sabotage, but it gave a stunning demonstration of the vulnerability of some bridge designs -- and of America's infrastructure. "It was only a single bridge member or connector that cracked," says Abolhassan Astaneh-Asl, a professor of structural engineering at the University of California at Berkeley, "and that collapsed the whole bridge."

Following the disaster, Astaneh-Asl conducted nine days of analysis in Minneapolis as part of his two-year, National Science Foundation-funded research into how bridges respond to bomb attacks, and how they can be retrofitted to withstand the worst. "With buildings, we can protect them from car bombs by having a stand-off distance, like on Pennsylvania Avenue [in Washington, D.C.]," he says. "But bridges are for cars, so we can't do that. Our main line of defense is taken away from us." ..........

........the Federal Highway Administration conclude that over one-quarter of the country's bridges are either structurally deficient or functionally obsolete. So while a successfully detonated car bomb will always cause some damage -- and possibly result in deaths -- Astaneh-Asl insists the job of engineers is to limit the scope of the damage, as opposed to preventing it altogether: "The crucial question is whether the local blast will cause global instability in the structure." There are three main types of bridge structures and, based on their method of construction and level of risk, America's bombproofers are tackling each one:

1. Suspension Bridges Many of the biggest, most inviting terrorist targets are the spans carried by one main cable, such as the Golden Gate Bridge, which packs 70,000 strands of quarter-inch-thick steel into its primary suspension. The good news, other than that the Bay Area wil get a new $6 billion, quakeproof span by 2013? Suspension bridges are already the most difficult to damage with a car bomb, since the primary cable rests so high above the roadway. Plus, the cable's flexibility makes it relatively immune to bomb blasts. "It's like if you try to hammer a rope, you're not going to do much damage," Astaneh-Asl says. -

2. Cable-Stayed Bridges With cables fanning out from a central tower to directly support the roadway, pulling both ends of the bridge deck toward the center, any small portion of a roadway that goes down could wipe out an entire bridge of this kind. Scientists saw this during the Allied bombing of Germany in World War II, where bombers were able to knock down many cable-stayed bridges even with near misses. Now Hynes's team at Fort Knox is studying ways to defend spans with a multilayered approach. They are starting with construction techniques such as an outer layer that could be a simple PVC pipe, a wrap made of Kevlar or some other strong fabric, and potential fillings such as pea gravel, pumice chips, sand or paintballs. "We want a series of layers that each does different things," she says, "and together they absorb or reflect the energy of the blast, and disrupt the coherence of the wave." Astaneh-Asl, meanwhile, sees vulnerabilities in the roadway and bridge tower themselves, and recommends strengthening the bridge tower for 20 to 30 feet above the road and 10 to 20 feet below with a jacket of steel plating -- a technique that has already been implemented for seismic protection on some California bridges.

3. Truss Bridges Scientists have bemoaned these structures since long before the steel trusses on I-35 gave way this summer. "We have hundreds of these bridges built between the 1950s and 1970s," Astaneh-Asl says, "and they're like a house of cards -- remove one piece, and you're in trouble." It is possible to retrofit these bridges, however. One approach is to add cables inside the bridge members to take some of the load; another is to wrap the bridge column in fiber-reinforced polymer composite tape to add strength. Or additional bridge members can simply be added alongside the original sections to create redundancy -- an approach that was recommended for the Minneapolis bridge by external consultants in 2006, but never implemented.

(Click here for full news story)

_________________________________

Why bridges fail

Published: 15 August 2007 06:37 PM,

Source: The Engineer Online

A University of California, Berkeley civil engineer has criticised the design of the bridge that collapsed earlier this month in Minneapolis.

'Truss-arch' structures, such as the collapsed Minneapolis freeway bridge are susceptible to fatigue and collapse, making them 'a very bad system,' claimed Berkeley professor of civil and environmental engineering Abolhassan Astaneh...........

.....................

Astaneh says there are no truss-arch bridges in the San Francisco Bay Area and none that he knows of in California. The closest local approximation is the Benicia–Martinez Bridge, a truss bridge that he inspected with Caltrans engineers about 15 years ago. The Benicia-Martinez Bridge, also known as the George Miller Jr. Bridge, crosses the Carquinez Strait just west of Suisun Bay, linking Benicia, California in the north with Martinez, California to the south.

The inspection turned up early signs of fatigue - microcracks in plates welded to the top of the members - that Caltrans, the state agency responsible for highway, bridge, and rail transportation planning, construction, and maintenance. was able to cut out and replace.

'As soon as the cracks developed, it was fixed and everything was fine,' said Astaneh.

Astaneh has led National Science Foundation investigations into the collapses of the World Trade Center and MacArthur Maze, a complex of freeway interchanges located near the eastern end of the San Francisco-Oakland Bay Bridge in Oakland, California. (Click here for full news story)

_________________________________

Other states' experiences inform debate over bridge rebuild timeline

by Tom Scheck, Minnesota Public Radio, August 15, 2007

St. Paul, Minn. — A large part of the hearing focused on whether the rush to get the bridge rebuilt would jeopardize quality. Lawmakers wanted to know if MnDOT was thinking long term -- in particular, would the project be flexible enough to last the 100 years it's designed for.............

Hassan Astaneh, a professor of structural engineering at the University of California Berkeley, says accelerated construction is becoming more standardized in the country.

"Most major bridge construction companies are now getting the jobs because they have been able to develop the technology for accelerated construction, and come in with bids that they are going to do the job but they are going to do it faster," said Astaneh. (Click here for full news story)

_________________________________

Design Flaw Cited in Bridge Collapse

By FREDERIC J. FROMMER Associated Press Writer,

WASHINGTON January 15, 2008 (AP)

Abolhassan Astaneh-Asl, a professor of civil and environmental engineering at the University of California at Berkeley and an expert on gussets, spent 10 days in Minneapolis after the collapse gathering information for his own research.

"I concluded that the construction load may have been the last straw," he said.

(Click here for full news story)

_________________________________

Minnesota picks preliminary design for bridge to replace fallen span,

by Tom Scheck, Minnesota Public Radio,Dan Olson, Minnesota Public Radio, August 14, 2007

Minneapolis — The aerial sketch is simple. It shows two side-by-side bridges that will each hold five lanes of traffic running in opposite directions over the Mississippi River. The old 35W bridge had four lanes in each direction.

Hassan Astaneh, a professor of engineering at the University of California Berkeley, says the public shouldn't be concerned that an accelerated construction process would discount safety. He says states and contractors have nearly perfected the so-called design/build process in the past decade.

At this point, Astaneh he says it doesn't make a difference if a contractor takes their time or builds the bridge on an accelerated basis

"All of it is really to optimize your construction methods not to change design code, which is the document that you use for design and issues of safety. So I can't see any reason why people should think that if you do it fast that it will not be as safe as if you build it slowly," he said. (Click here for full news story)

_________________________________

Bridge Plates Not Cause For Concern, Officials Say

By Michael Laris, Washington Post Staff Writer,

Friday, August 10, 2007; Page B01

Connectors known as gusset plates, which federal officials are scrutinizing as part of their investigation into Minneapolis's Interstate 35W bridge collapse, are a common feature of steel spans in the Washington region and across the country........

..........

....

Some outside bridge engineering experts say officials would be better off not only inspecting deck truss bridges but also other truss bridges built in the 1950s and '60s.

Abolhassan Astaneh-Asl, a professor of structural engineering at the University of California at Berkeley, said "there's no reason to believe" that a truss bridge with a deck on top of its steel supports -- a deck truss -- has more "critical gusset plates" than a truss bridge in which the deck is below the supports. ........... . (Click here for full news story)

_________________________________

BY CHRISTOPHER SNOWBECK, JASON HOPPIN and DAVE ORRICK, Pioneer Press, August 9, 2007,

Updated: 01/15/2008 07:25:12 PM CST

Investigators seeking the cause of the Interstate 35W bridge collapse are looking closely at steel plates that tied together beams in the center span of the structure, a state-hired consultant said Thursday....

........And a University of California-Berkeley engineering professor said he might narrow the focus even further, having calculated which set of plates on the bridge constituted the weakest gusset points......

Abolhassan Astaneh-Asl, a structural engineer at the University of California-Berkeley who specializes in steel and composite bridges and buildings, said he analyzed blueprints for the bridge and calculated that gussets located just inside the piers at "U10" on the drawings were the weakest points. These gussets, at a half-inch thickness, might have been fine had the bridge been better maintained, said Astaneh-Asl, who has reviewed inspection and consultant reports on the bridge.

"You're close to the margin," Astaneh-Asl said. "If you don't inspect your bridge to make sure that your margin is being kept, you might end up with a problem."

Although the gussets at U10 were the weakest points, it's likely other gussets would be closely considered by investigators, Astaneh-Asl said.

Noting that studies showed traffic was heavier in the southbound lanes of the I-35W bridge - and that trucks bringing heavy loads into the city center would have been lighter on the northbound return trip - Astaneh-Asl said he thought something on west side of the bridge likely gave way first. The theory was furthered, he said, by what he called the "eccentricities" of the load of construction equipment that evening in the bridge's southbound lanes.

It's likely a combination of factors caused the collapse, he said.

That was echoed by investigators Thursday, who cautioned that many factors will likely come into play and that the catastrophe is extremely unusual. "Bridges don't fall. We knock down bridges," Magladry said. ...........(Click here for full news story)

_________________________________

Metal plates examined in bridge collapse

By MARTIGA LOHN Associated Press Writer, in Pioneer Press Newspaper, August 9, 2007,

Updaed 01/15/2008 07:25:23 PM CST

MINNEAPOLIS—The metal plates that held the girders together on a failed 1960s-era interstate bridge were originally attached with rivets, old technology that is more likely to slip than the bolts used in bridges today.

Some of the plates, or gussets, also may have been weakened by welding work over the years, and some of them may have been too thin or too small, engineering experts said Thursday. ..........

..The bridge's builders in the mid-1960s riveted the plates together, which required many more holes than bolts would have. More holes weaken steel, said Abolhassan Astaneh-Asl, a professor of structural engineering at the University of California-Berkeley, who likened it to Swiss cheese. ...... ...

Astaneh-Asl reviewed construction drawings of the bridge from 1965 that showed varying thicknesses of the gussets. Some in key spots over the Mississippi River were only a half-inch thick, he said, and his rough calculation of the pressure they could withstand suggested they were weaker than the beams they connected. A cracked gusset is visible in photographs taken after the collapse, he said, but it's unclear what role that might have played in the bridge's failure. ........ .(Click here for full news story)

_________________________________

The big question: Why did the bridge fall down?

by Sea Stachura, Minnesota Public Radio, August 8, 2007

Minneapolis , Minn. — When the 35W bridge collapsed last week, it was 40 years old. .....

........

University of California Berkeley professor Hassan Astaneh says between 1950 and 1970, bridge members -- as the support beams are called -- were welded together. Astaneh knows a lot about bridges of this era. He served as the research arm for the California Department of Transportation in 1987, when it was dealing with a similarly troubled bridge as the 35W. He was also the primary investigator of the World Trade Center collapse for the National Science Foundation. Bridges today aren't built with the same type of welding. But at one time, welding was considered a fast, cheap way to build.

"The designers of these bridges did not know anything about fatigue. It was during the 1970s, early 1970s, that some welded bridges built in 1950s -- they developed fatigue cracks," said Astaneh.

These cracks are hair fractures in the steel, Astaneh says, and they generally show up at the points where the steel is welded. They're caused by cycles of traffic stressing the bridge structure.

Bridges are designed to bear one and a half to two times their intended weight, Astaneh says. That margin is a safety net that accounts for design errors.

MnDOT had already eaten into the bridge's safety net when it added two inches of concrete to the deck in 1998, Astaneh claims. The 35W bridge deck was nine inches thick. Normally a bridge's deck is six to seven inches thick, Astaneh says.

. (Click here for full news story)

________________________________

A "HOUSE of cards" is how some engineers describe the steel-truss system used on the Interstate 35W bridge that collapsed into the Mississippi River, saying that almost any piece of the complex design that failed would have brought down the entire span.

Experts said yesterday that it was too early to speculate about the specific causes of Wednesday's bridge failure, but most previous failures of bridges over rivers have been for a handful of known reasons: weak foundations, corrosion, metal fatigue, ship collisions and errors in the original design.

The I-35W bridge was entirely supported by two main trusses, composed of many small pieces of steel bolted or welded together like a child's erector set.

"A truss-arch bridge is like a chain — if you try to take out one link, you lose the whole system," said Abolhassan Astaneh-Asl, an expert in steel-truss bridges at the University of California, Berkeley.

"They are very vulnerable to instability."

Mr Astaneh-Asl compared a steel-truss system to a house of cards, which will collapse quickly if one card is pulled out.

The collapse has already triggered a renewed examination of the nation's deteriorating highway system.

Deficient bridges are part of an estimated $US200 billion worth of infrastructure improvements needed across the nation, according to Priscilla Nelson, a civil engineer at the New Jersey Institute of Technology.

. (Click here for full news story)

__________________________________

Midmorning Hour 1 (9:00 am) Broadcast, Minnesota Public Radio

Interviewer: Sea Statura

Guests: Hassan Astaneh Professor, structural engineering at University of California at Berkeley. He's the lead investigator of the Oakland highway bridge that burned and collapsed in April. Also joining in the conversation, C. V. Shashikumar, president and founder. C. V. Associates, Inc., a bridge inspection firm.

|